PRODUCT DEVELOPMENT

REIMAGINED

About

Veluon is a product development, commercialisation, and investment company, working with clients worldwide, from the concept stage including technology, funding, and manufacturing feasibility, all the way up to market launch and beyond.

We work with clients in a wide range of capacities to bring their ideas to fruition, from sitting on boards providing technical and operational guidance for management teams, to fully fledged turnkey total development contracts.

Services

Product Development, Commercialisation, and Investment

For product development, our engineers have extensive skills in mechanical, electronics, optical, firmware, supply chain, product design and manufacturing. We primarily serve medical devices and consumer electronics also providing assistance outside of these fields. We pride ourselves on rapid product development by taking advantage of our global supply chain network and work to the relevant quality and regulatory standards.

For commercialisation, we provide assistance in a variety of capacities from technical consultancy, patenting, sitting on boards, optimizing route to market with funding milestones in mind, and preparation for investment pitches.

For investment, we find companies commonly need funding for their development and operations and we often invest in businesses through various means.

Know-How

Our technical know-how used in client’s projects as required.

Project Management

- Technical Feasibility Assessment (TRL Level)

- Project Management

- Project Proposals and Costing

- Minimum Viable Product Assessment

- Life Cycle Analysis

R&D & Engineering

- Product Design

- Electronics Engineering

- Mechanical Engineering

- Optical Engineering

- Firmware Engineering

- Software Engineering Liaison

- Prototyping and Instrumenting of Systems

- Design for Compliance/Regulatory Standards

- Design/Refine for Manufacture/Assembly

- Design Failure Analysis

- Certification Testing – i.e. EMC/Electrical Testing

Manufacturing & Supply Chain

- Production Planning

- Cycle Time Optimization

- Supply Chain Implementation

- Supply Chain Optimization

- Supply Chain Logistical Support

- Contract Manufacturing Liaison

- Quality Control

- Technical Documentation

Commercial & Operations

- Commercialisation Strategy

- Subcontractor Management

- Intellectual Property Optimisation

- Investor Relations Support

- Investment Pitches

- Investment Rounds (incl. SEIS/EIS)

- Nominated Board Members

- Equity Investing and Optimization

Team

Entrepreneurial engineers with vision

Veluon was founded by 3 engineers who have a proven track record for developing innovative products, implementing production systems, setting up manufacturing plants, and running technology businesses. They have unsurpassed experience between them in a range of industries including Academia, Aerospace, Automotive, Biomedical and Consumer Electronics. They previously started and grew one of the fastest growing medical start ups in Europe, developing next generation medical devices for optometrists and the optical industry expanding it to a multi-national enterprise with 60 employees including 40 Engineers and its own production facilities. All of this positions them perfectly to work with those who are embarking on the journey to bring products to market and help them navigate the process.

The wider team consists of PhD and Masters level Engineers who are specialists in their fields and Veluon works with a network of subject matter experts as the project requirements emerge.

Thomas has led the development of multiple projects from R&D phases all the way through to commercialisation utilising UK and Asian supply chains. These include class 1 and 2 medical devices requiring FDA and MHRA certification. He has numerous scientific publications and is regarded as a subject matter expert holding numerous patents. He has founded companies with combined values in excess of £15M and has raised over £12.M of investment from mixed sources. Thomas is also believed to be the youngest ever awarded a chancellor’s medal from Aston University for his academic and industry collaboration services.

Previous Experience (15 Years)

- Chief Technology Officer/Founder of Eyoto Group Limited

- Executive Vice President/General Manager of Eyoto’s custom projects division (responsible for OEM and white label design of products for established equipment companies).

- Acting Chief Operations Officer at Eyoto Group Limited (responsible for setting up the UK production facility.)

- Lecturer and Head of Biomedical Engineering at Aston University

- Multiple Postdoctoral and Research Roles (Johnson and Johnson, Astellas Pharma etc.)

Education

- Ph.D. Ophthalmic Engineering at Aston University (Specializing in Electro-mechanical/optical design)

- [1st Class] BEng (Hons) Degree in Mechanical Engineering at Aston University

- Foundation in Aerospace Engineering at Kingston University

Suraj is a founder of Veluon Ltd. and former Vice President of Engineering at Eyoto Group Ltd. He has managed in excess of 10 product development cycles to date from Class 1 and 2 medical devices to consumer electronics. He is a specialist in rapid product development with a background in Ophthalmics (Biomedical). He has a strong skillset in managing teams of technical and non-technical people and cross departmental collaboration. He is adept in Project Planning, Product Architecture, Systems Integration, Idea Conceptualization, Mechanical Design (CAD), modern and rapid development/manufacturing (CAM), and has overseen the accelerated development of 3 medical devices in 13 months. He holds numerous patents, and has also worked for one of the largest aerospace companies in the world. He holds a First class Honours Degree in Mechanical Engineering and an MSc with Distinction in Ophthalmic Engineering.

Previous Experience (7 Years)

- Vice President of Engineering at Eyoto Group Limited Suraj was responsible for day to day management of Hardware Engineering teams, overall Project Management and systems integration by working in collaboration with R&D, Software, Marketing and Quality/Regulatory departments to develop products. With oversight of product architecture he specialized in systems integration, designing and coordinating complex parts and assemblies utilizing modern forms of manufacturing. He was an architect of Eyotos manufacturing system for production that was recognized by the industry as a world class system.

- Mechanical Engineering Manager at Eyoto Group Ltd.

- Mechanical Engineer at Eyoto Group Ltd.

- Test Engineer at UTC Aerospace Systems Ltd. (Responsible for designing tests and developing rigs to compare performance (pressure, flow rate, temperature), of fuel manifolds of various jet engines, simulating real working conditions, that were manufactured at two separate manufacturing plants.)

Education

- [Distinction] MSc By Research in Ophthalmic Engineering at Aston University

- [1st Class] BEng (Hons) Degree in Mechanical Engineering at Aston University

Jordan has set up manufacturing facilities and supply chains from high value small batch products requiring high level operator skill with minimal automation through to short cycle time, high volume automated production. Specializing in the management of rapid development projects, leveraging vertical integration through setting up a 5000 Sq Ft innovation centre, to speed up the iterative design process and build of initial customers units prior to transferring to a contract manufacturer. He has managed multimillion-pound projects delivering them from the beta stage through to production, created and implementing a business wide document and part ID system plus the Eyoto manufacturing system.

Previous Experience (6 Years)

- Innovation and Special Projects Manager at Eyoto Group Limited (Responsible for the management of large custom projects at Eyoto, covering both commercial and technical aspects. Managing the EMC and Electrical Safety compliance testing for CE and FCC.)

- Transfer to Manufacture Manager at Eyoto Group Limited (Focused on design for manufacture and design for production on all Eyoto branded and custom projects. Managed the design for manufacture hardware engineering team and worked extensively with a wide variety of suppliers in the EU, USA and Asian supply chain.)

- Production and Quality Specialist at BMW (Responsibilities included commissioning of new Oxford BIW facility. Maturing the quality of vehicles from prototype stage through to series production. Process improvements resulting in savings of £1M+)

Education

- [1st Class] MEng (Hons) Degree in Mechanical Engineering at Aston University

Process

Collaborative, end-to-end process.

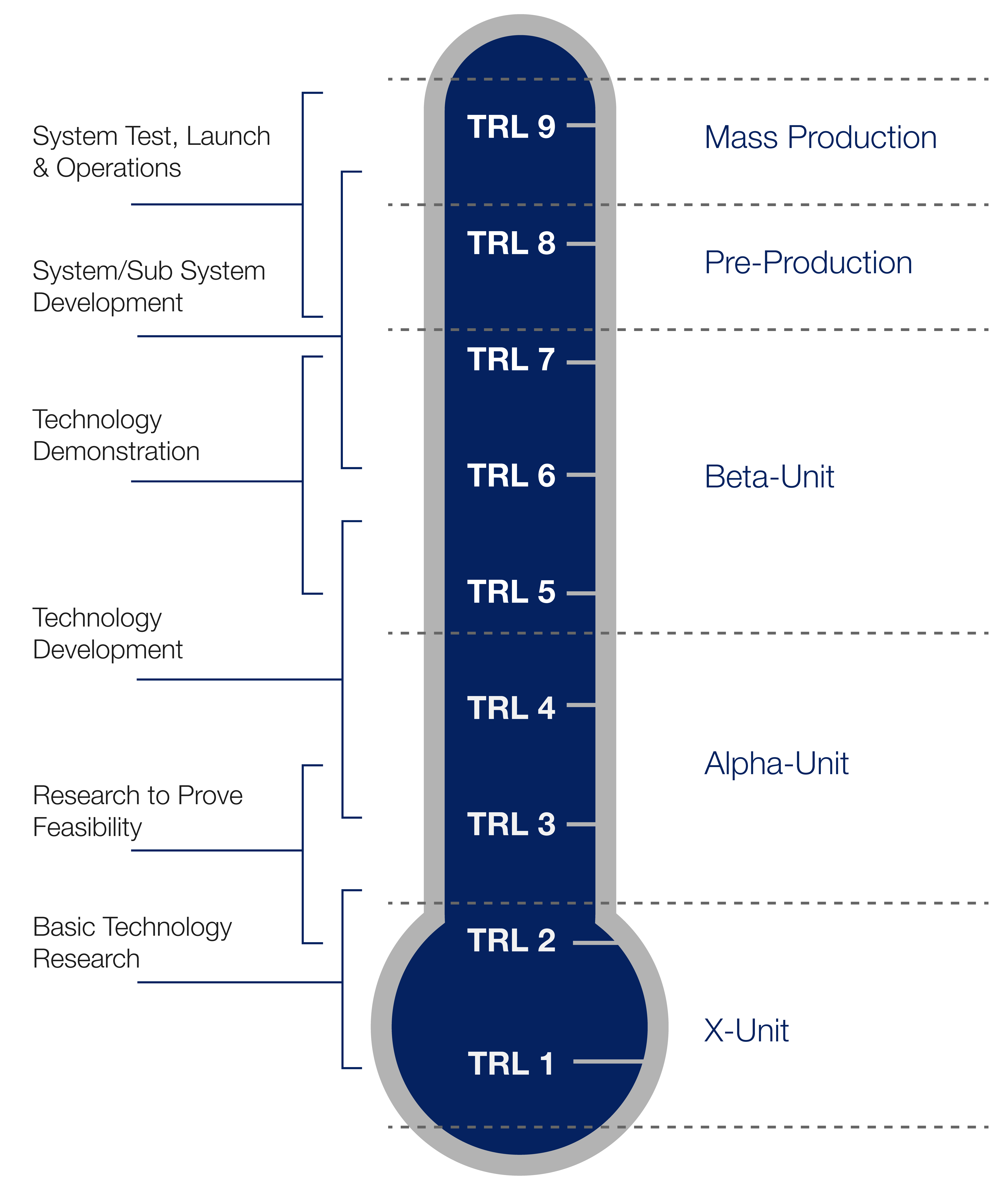

Product Development is like a multi-dimensional puzzle – intricate, multifaceted with lots of moving parts and stakeholders. and so needs to be structured and managed effectively. We use the NASA invented ‘Technology readiness level (TRL)’ system for establishing the maturity of the technology and consolidate this into 5 development stages as shown in the diagram below.

Workflow

All ideas then need to be developed in the 5 workflows as detailed below. These elements need to seamlessly intertwine to create an end product that fulfills its requirements, is manufacturable and marketable.

Feasibility Assessment

Establish the current Technology Readiness Level1 (TRL). Assess the viability of the idea/concept or conceptualise solutions to the problem that is being addressed. Identify the technology and direction that would be required in order to develop the solution for TRL 8/9. Develop concepts and early prototypes as proof of principle of the technology chosen to assess feasibility.

Design & Development

Detailed technical development of the product which involves developing proof of concept prototypes, or building upon existing prototypes. Undertaking all relevant design work (electronics, mechanical, optical, product design, etc.) and ensuring the regulation framework is complied with.

Manufacturing & Supply Chain

Establish supply chain to source components required to match scaling and output of production and implement production processes and lines. This will include any quality control processes that may be required. We have partners we work with across the world from Asia to the US to fulfill requirements.

Regulation & Compliance

If the product is regulated or used in a regulated market (i.e. medical), ensure correct rules and procedures are followed and implemented in design and manufacturing processes in order to undertake regulatory testing for the required certification. We have multiple partners we work with on this including TUV.

Market Launch & Life Cycle Assistance

Once all the above is in place, the customer will be in a position where they can order X amount from our assembly/manufacturing partners similar to how you would order from Amazon taking away all the complexity. You can have the option of keeping Veluon onboard monitoring production post-launch

Pricing

insert subtitle here

Veluon has a novel approach to the development of products for customers. Our experience has taught us that custom product development projects are very difficult to define in the early stages of a project, before the full customer requirements are clear, therefore it is better to have a collaborative type of relationship to deliver an end-to-end solution for the customer.

The traditional method companies use for developing products would be to agree on a rigid specification then deal with every change required as a project scope change. The development cost is then increased, after a customer is locked into the process, when changes are needed to be made. Veluon does not believe in this method and our experience has indicated there are better ways to work together.

Day Rate Model

Projects are appraised, and an estimated timeline of company work days is given.

Royalty Model

The day rate for the number of company days required to complete the project is heavily discounted all the way up to cost price. The discount for development is exchanged for a royalty per sale of the product once on the market and/or equity.

Fixed Unit Cost Model

This model resonates with those who have a fixed number of units they need developing over a particular time period. The development is appraised and calculated, price and volume over an agreed time frame are agreed and the overall cost is consolidated into one figure and amortised over a time period to optimise cash flow requirements.

Fixed Development Model

In this model, we charge a fixed development cost for the project and is generally recommended for use on products where objectives are clearly defined and the R&D required is minimal.

Projects

insert subtitle here

Veluon’s business model is to deliver a solution to the customer in a fair and transparent manner. Depending on the option selected, we will agree to develop a technical solution and share some of the technical risks by developing the product at a significantly reduced price in exchange for a Sales royalty.